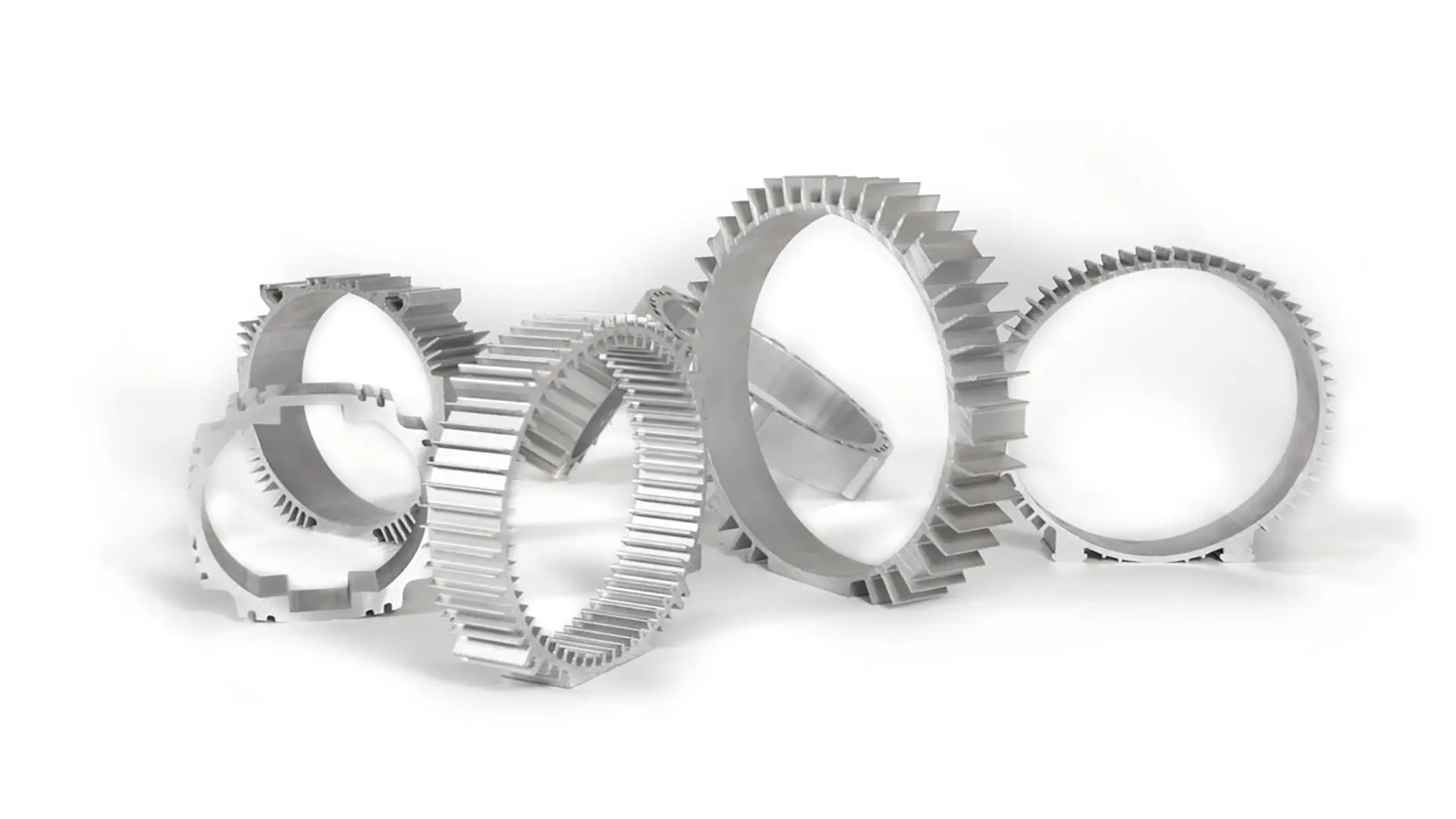

In today’s world, the use of aluminum profiles in various industries, especially in the electrical and electronics sectors, has sharply increased. One of the important applications of this material is the manufacturing of the housing or external body of industrial and domestic motors. The design and production of motor housings using aluminum profiles offer a combination of high strength, low weight, and suitable thermal performance, features that have made it highly popular among electrical equipment manufacturers.

The aluminum motor housing is essentially a protective enclosure that surrounds the motor and plays a crucial role in cooling and protecting the internal components of the motor. Manufacturing this housing from aluminum profiles leads to:

- Reduced motor weight,

- Faster dissipation of heat generated during operation,

- Increased resistance of the device to rust, moisture, and pressure.

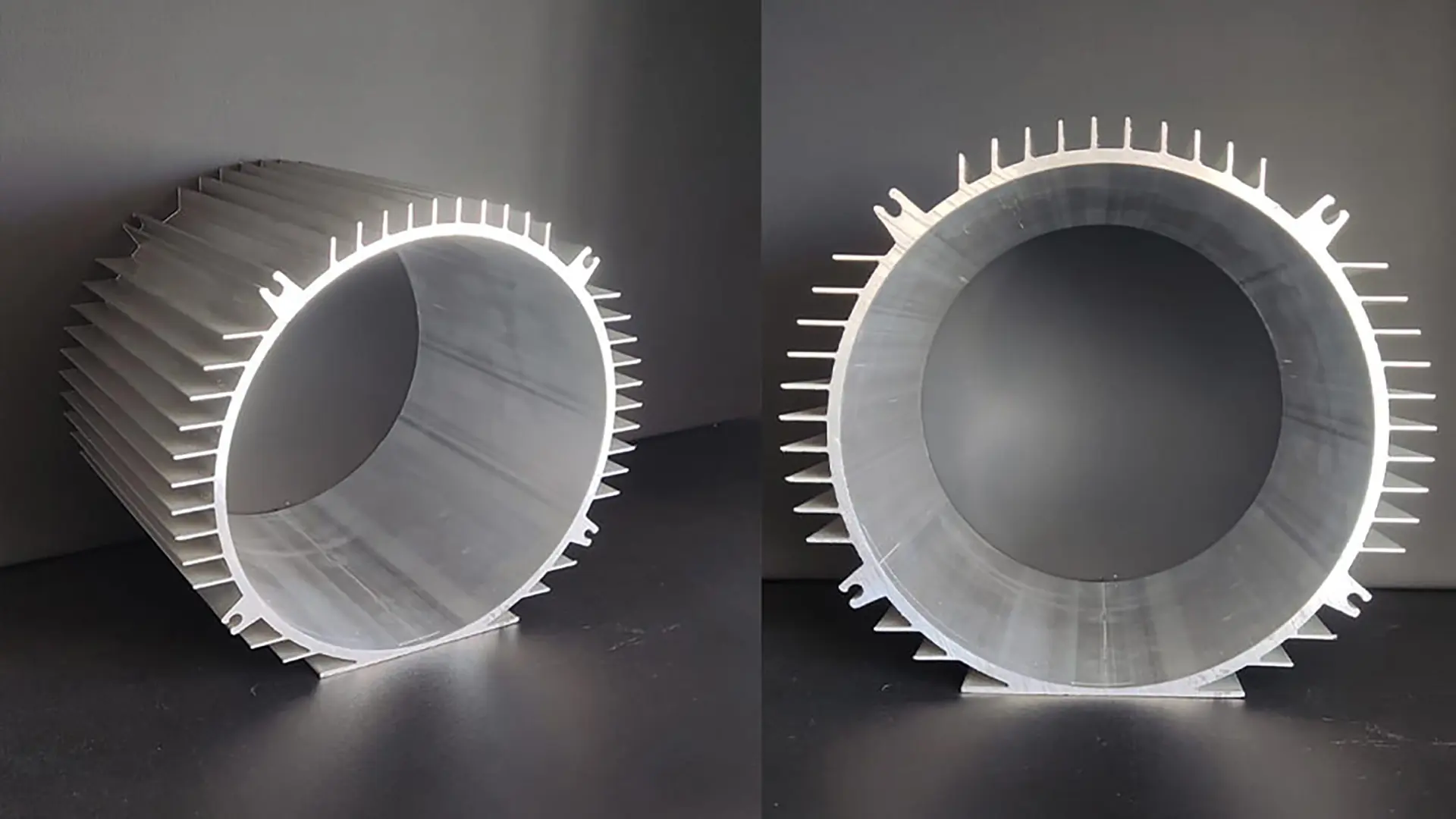

Due to its high thermal conductivity property, aluminum can rapidly transfer the internal temperature of the motor to the surrounding environment, preventing damage to sensitive electronic components. This characteristic directly leads to increased efficiency, durability, and safety of the motor.

Applications of Aluminum Motor Housing

Today, aluminum housings are used in various types of light and heavy motors. These housings not only improve motor performance but are also preferred in many types of equipment due to their modern appearance and light weight. Some of the most common applications of aluminum profiles in manufacturing motor housings include: Motors for HVAC (Heating, Ventilation, and Air Conditioning) systems Air compressors Motors for industrial and electronic devices Blowers and negative pressure fans Micromotors and various motors in portable tools Furthermore, due to their high resistance to corrosion and decay, aluminum housings perform very well in humid or dusty environments, reducing the need for frequent repairs.