Aluminum profile refers to engineered sections made from aluminum or its alloys, typically produced using the extrusion method (pressing through a die). In this process, molten aluminum is passed through molds with various shapes to achieve the desired form. The result is a profile with a uniform cross-section and a defined length, which can be either hollow or solid.

Outstanding Features of Aluminum Profiles

Aluminum profiles, due to their unique properties, are an ideal choice for many industrial and construction projects. Some of their key advantages are: Lightweight compared to many other metals like steel, high resistance to corrosion and rust, attractive appearance and a glossy surface that can be painted or anodized, high formability, cutting, welding, and machining capabilities, good thermal and electrical conductivity, high durability in various weather conditions.

Applications of Aluminum Profiles

Aluminum profiles are used in various fields, including: Construction industry: Use in double-glazed doors and windows, modern facades, internal partitions, false ceilings, and electric shutters. Transportation industry: In the construction of car bodies, trains, and lightweight equipment. Home appliances and lighting industry: Production of LED panel frames, bodies of coolers, and domestic machines. Industrial and engineering structures: Construction of industrial frames, equipment bases, machinery, and assembly lines. Interior decoration and furniture: Picture frames, furniture profiles, railings, and handles.

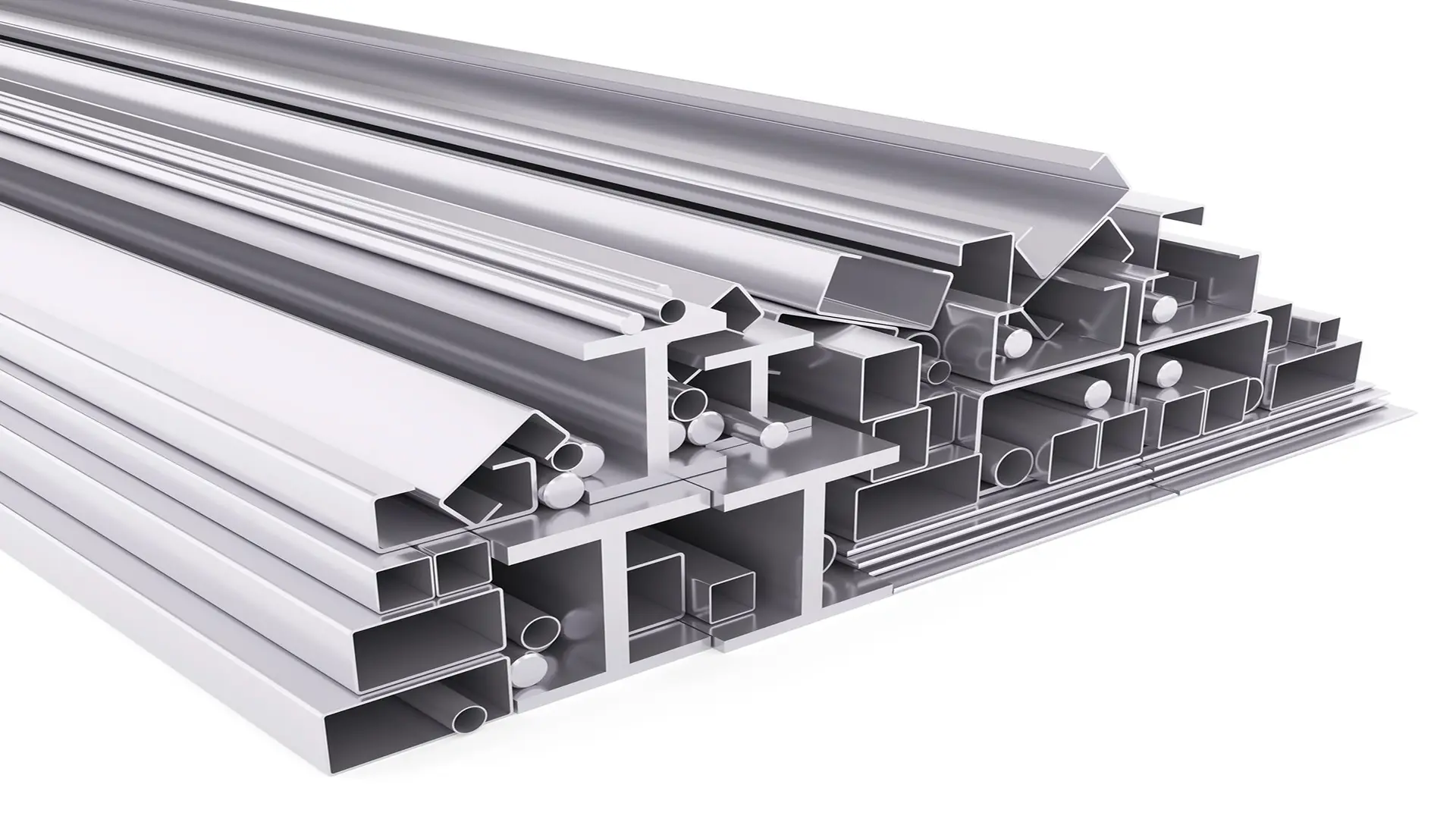

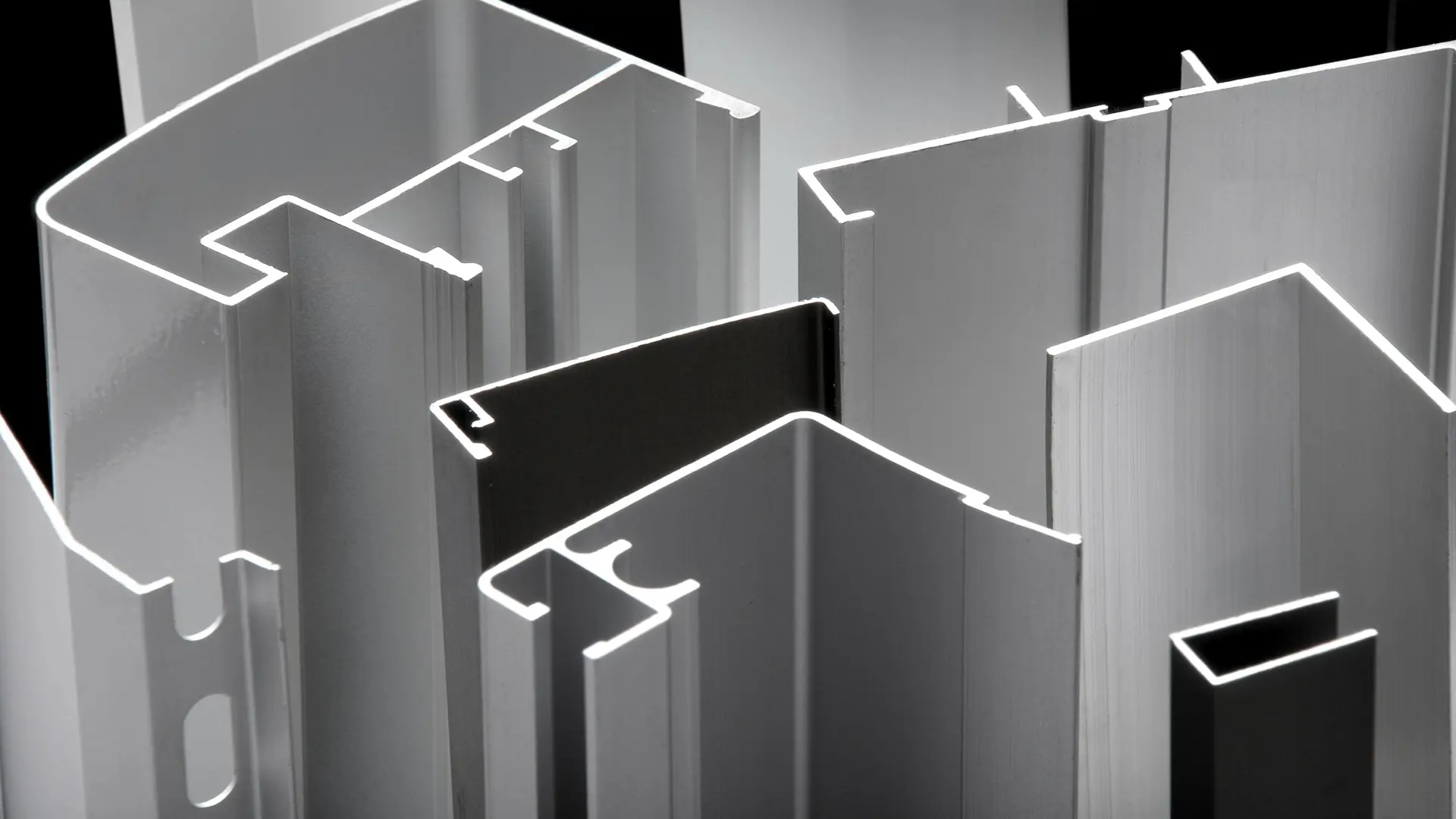

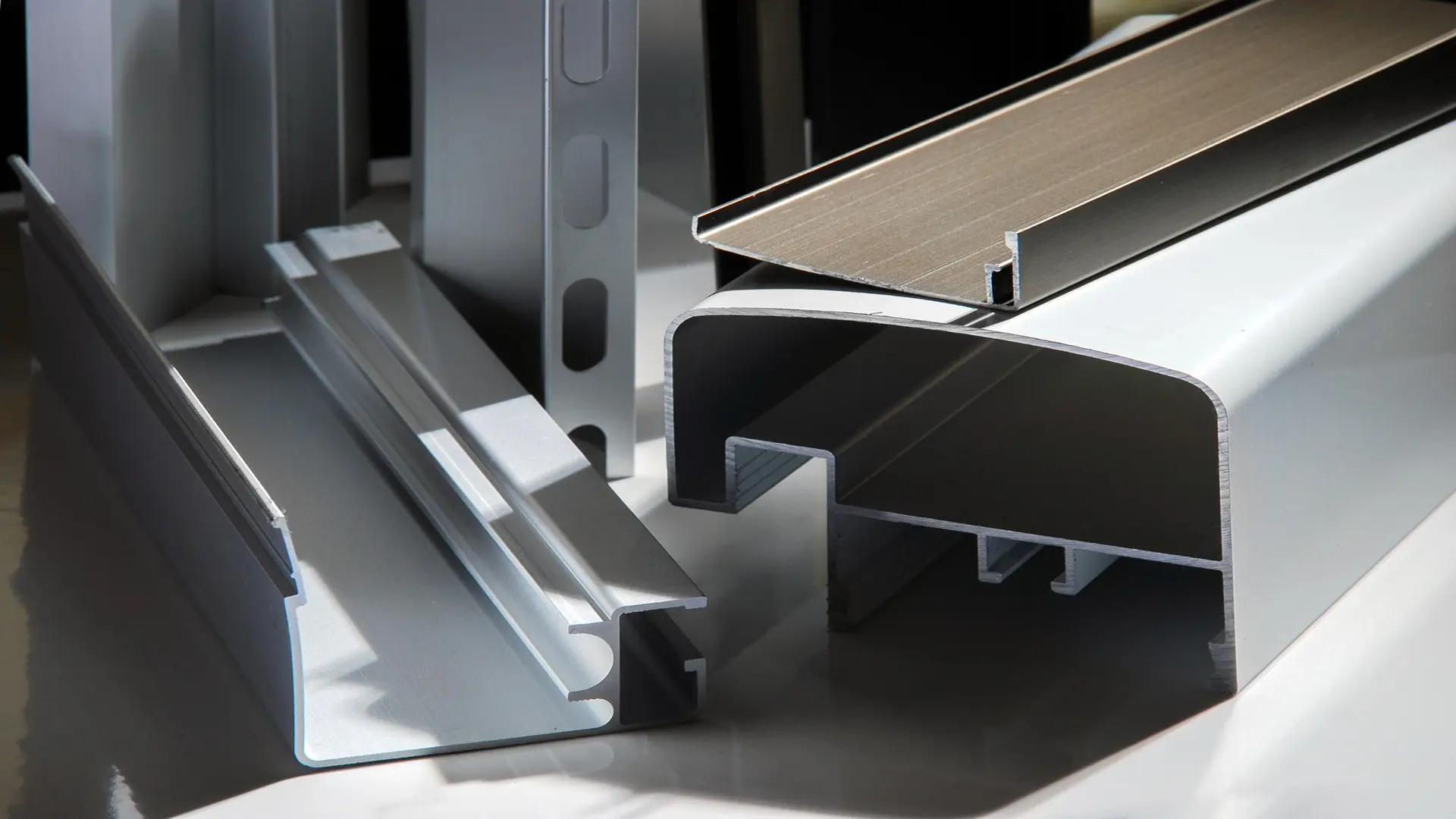

Types of Aluminum Profiles

Aluminum profiles are produced in various dimensions and shapes, the most common of which include: Box profiles, strip profiles, angle and T-bar profiles, custom and industrial profiles with custom designs. Also, depending on the need, the profile surface can be coated with electrostatic powder coating, anodizing, or a wood grain finish. Summary Due to its unique combination of lightness, strength, beauty, and high workability, the aluminum profile has become one of the most widely used metal sections globally. This product holds a special place not only in the construction industry but also in a wide range of other industries. Due to its high variety, customizability, and rapid production process, it has attracted the attention of many engineers and designers.