Aluminum Production Process

The aluminum production process generally consists of several key stages:

Bauxite Extraction from Mines: Bauxite, the primary raw material for aluminum extraction, is mined from various locations around the world.

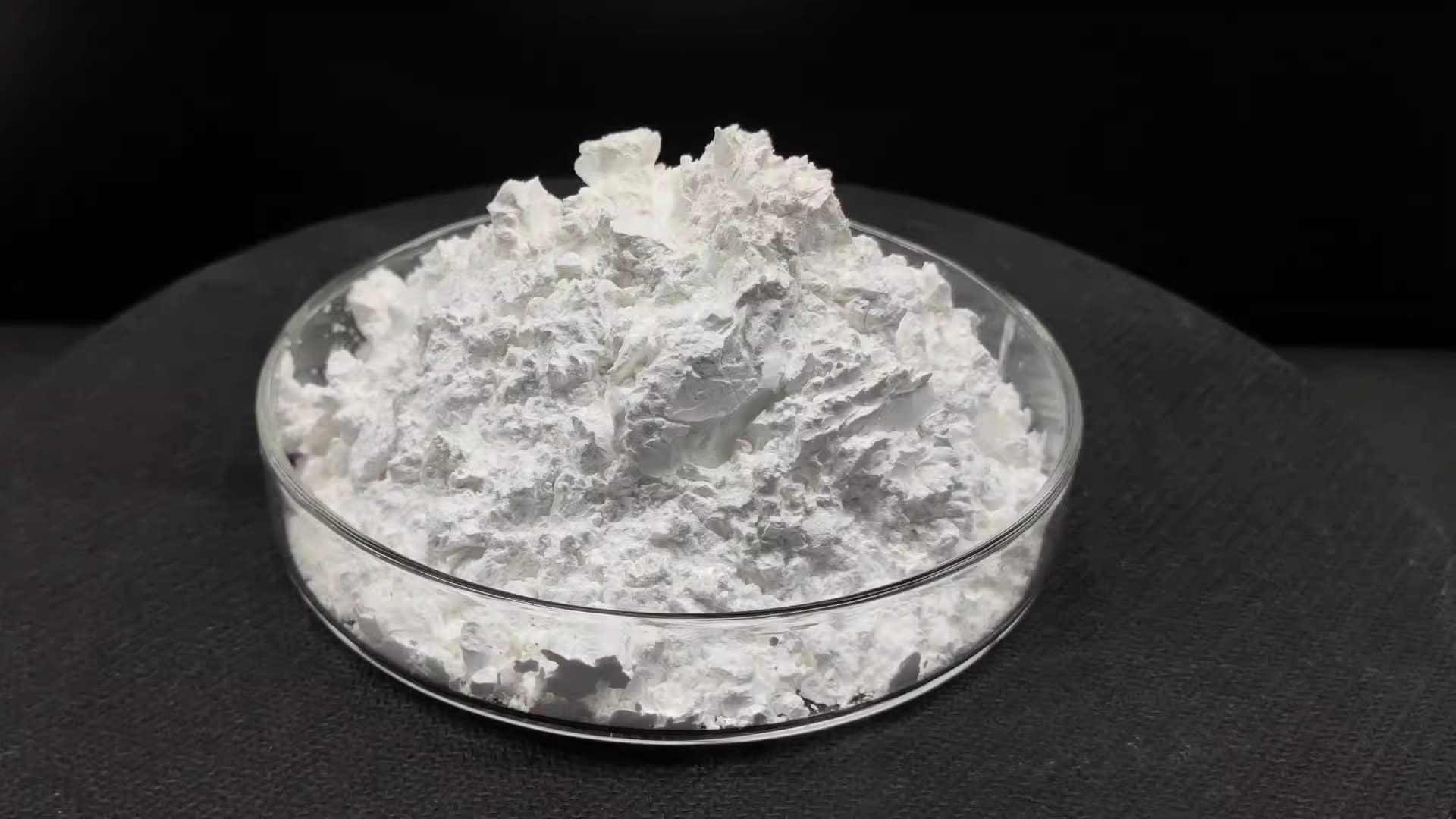

Production of Alumina from Bauxite (Bayer Process): Bauxite is first crushed and mixed with caustic soda. Then, by heating the mixture, alumina is separated from impurities.

Alumina Electrolysis: Alumina is converted into molten aluminum in Hall-Héroult electrolytic cells. In this process, alumina is broken down by electric current into aluminum and oxygen.

Aluminum Casting: After molten aluminum is produced, it is poured into molds and cast into ingots.

Conclusion

The production of aluminum is a complex and energy-intensive process that requires specific raw materials, such as bauxite, alumina, cryolite, and carbon. However, recycling aluminum can significantly reduce energy consumption and minimize pollution. By optimizing production methods and utilizing recycled aluminum, greater efficiency in production and reduced environmental impact can be achieved.